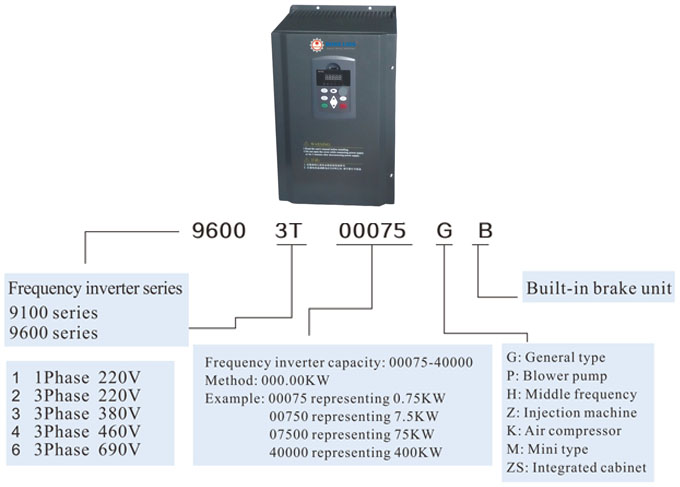

| Tên sản phẩm: | Biến tần inverter DL-9100 Series |

| Giá sản phẩm: | Liên hệ |

| Nhà sản xuất: | Dolin |

| Tình trạng: | Còn hàng |

| Bảo hành: | 18 tháng |

MÔ TẢ CHI TIẾT SẢN PHẨM:

| Voltage (V) | 220V | 220V | 380V | 460V | 575V | 660V |

| (1F) | (240V) | (415V) | (440V) | |||

| Power (KW) | Current (A) | Current (A) | Current (A) | Current (A) | Current (A) | Current (A) |

| 0.4 | 2.5 | 2.5 | ||||

| 0.75 | 4 | 4 | 2.5 | 2.5 | ||

| 1.5 | 7 | 7 | 3.7 | 3.7 | ||

| 2.2 | 10 | 10 | 5 | 5 | ||

| 4 | 16 | 16 | 8.5 | 8 | ||

| 5.5 | 20 | 20 | 13 | 11 | ||

| 7.5 | 30 | 30 | 16 | 15 | ||

| 11 | 42 | 42 | 25 | 22 | 17 | 15 |

| 15 | 55 | 55 | 32 | 27 | 22 | 18 |

| 18.5 | 70 | 70 | 38 | 34 | 26 | 22 |

| 22 | 80 | 80 | 45 | 40 | 33 | 28 |

| 30 | 110 | 110 | 60 | 55 | 41 | 35 |

| 37 | 130 | 75 | 65 | 52 | 45 | |

| 45 | 160 | 90 | 80 | 62 | 52 | |

| 55 | 200 | 110 | 100 | 76 | 63 | |

| 75 | 260 | 150 | 130 | 104 | 86 | |

| 83 | 320 | 170 | 147 | 117 | 98 | |

| 110 | 380 | 210 | 180 | 145 | 121 | |

| 132 | 420 | 250 | 216 | 173 | 150 | |

| 160 | 550 | 300 | 259 | 207 | 175 | |

| 187 | 600 | 340 | 300 | 230 | 198 | |

| 200 | 660 | 380 | 328 | 263 | 218 | |

| 220 | 720 | 415 | 358 | 287 | 240 | |

| 250 | 470 | 400 | 325 | 270 | ||

| 280 | 520 | 449 | 360 | 330 | ||

| 315 | 600 | 516 | 415 | 345 | ||

| 375 | 680 | 600 | 450 | 390 | ||

| 400 | 750 | 650 | 520 | 430 | ||

| 450 | 820 | 720 | 650 | 465 | ||

| 500 | 900 | 800 | 700 | 550 | ||

| 560 | 1000 | 900 | 780 | 590 | ||

| 630 | 1100 | 1000 | 850 | 680 |

Technical Standard of 9100 Series Frequency Inverter

| Item | Standard | |

| Power | Input | 3P 380V (1P 220V)50/ 60Hz |

| Allowed Variation | Effective voltage: 380V(220V)±15% | |

| Voltage allowance: ±15% variation; frequency variation: ±5% | ||

| Control | Control | Vector control without sensor, V/F control |

| Frequency range | 0-650 Hz | |

| Output frequency accuracy | ±0.01% of maximum frequency | |

| Frequency resolution | Keyboard setting: ±0.01% of output frequency | |

| ±0.2% of maximum output frequency | ||

| Voltage/frequency characteristic | 30%-100% rating voltage, adjustable base frequency 0.5- 640Hz | |

| PWM carrier frequency | 0.5-15.00 KHz | |

| Torque upgrade | 150% rating torque at 0.50Hz | |

| Overload ability | 60 seconds at 150% rating current, 10 seconds at 180% rating current | |

| Acceleration and deceleration | 0.1-3600 seconds | |

| Speed rate | No PG control: 1: 100 | |

| Speed accuracy | No PG control: ±0. 5% maximum speed | |

| Rating output voltage | Auto voltage adjustable function: When the voltage on the grid network changes, output voltage can automatically remain constant. | |

| Standard function | RPM trace, deceleration pause, PID control, auto speed compensation, auto voltage regulation (AVR), 8-step run, power (torque) control, frequency leap, simple PLC, UP-Down control, swing run, two-loop signal overlapping, auto reset, timer, flip-flop non-stop. | |

| Standard protection | Over-current, over-voltage, under-voltage, over-temperature, phase reversal and overload. | |

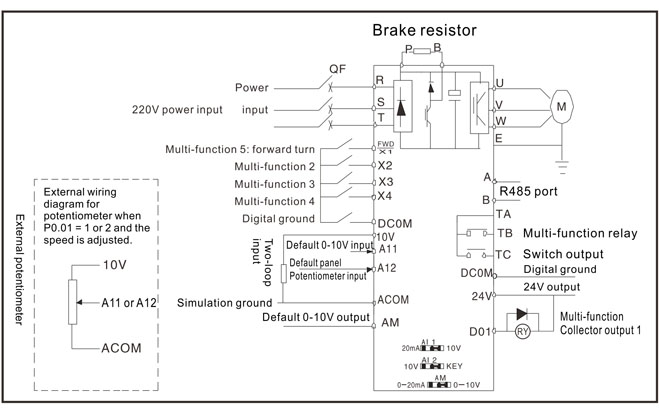

| Run | Frequency simulation input | External terminal Al1: 0- 10V |

| External terminal Al2: 4-20mA, panel potentiometer | ||

| Simulation output | External terminal AM, 0-10V or 0- 20mA | |

| Digital signal input | Programming input terminals for X1- X4 | |

| Digital signal output | One set of relay signal: 3A/ 250VAC | |

| One auxiliary signal output (open-collector electrode): 24VDC-50mA | ||

| Setting | Function, data, output current, output power for power factor angle, input power, power coefficient, timer time. | |

| Run | Output frequency, setting frequency, output current, input voltage, motor RPM, forward/backward turn, output power limit, conversion of output frequency and RPM, linear lead voltage, output voltage, temperature inside frequency inverter. | |

| Fault | Over-voltage, under-voltage, over-current ,over load over-temperature, over-voltage loss, data protection damaged, voltage limit, fault run, history fault. | |

| Environment | Installation location | Indoor, altitude less than 1000m, dust-free, no corrosive gas, no direct sunlight. |

| Ambient temperature and humidity | – 10~ + 40℃, 20%~ 90%RH (no condensation) | |

| Vibration | less 0.5g below 20Hz | |

| Storage temperature | -25~+65oC | |

| Installation | Wall mounted | |

| Protection grade | IP20 | |

| Cooling | Air cooling | |

Features of 9100 Series Frequency Inverter

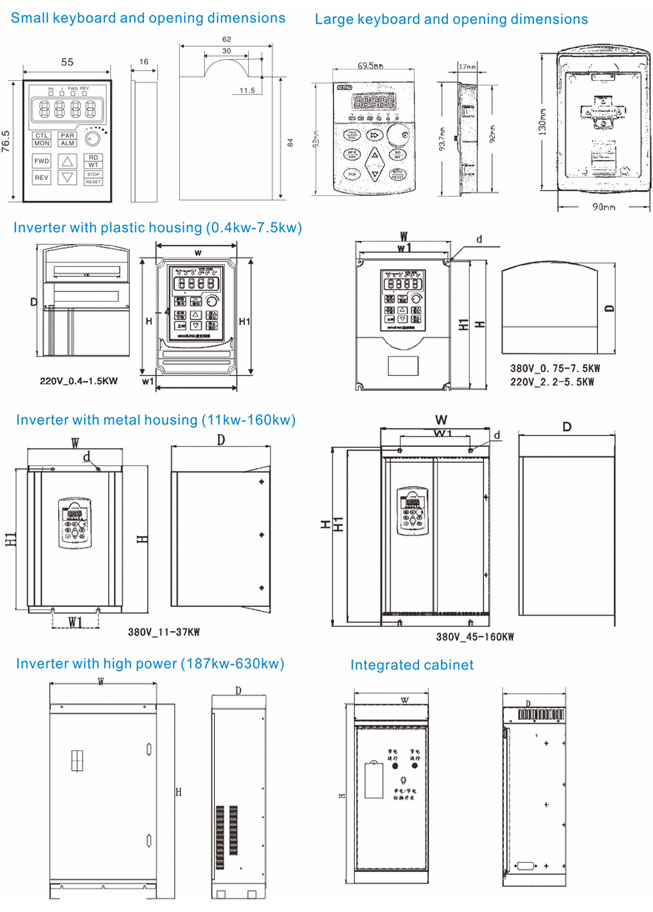

Frequency Inverter Dimensions and Accessories

Guide to brake assembly

The following table is the guidance data, where a user can select the resistance and the power according to the actual conditions (The resistance must not be less than the recommended value in the table, but the power can be increased.). The brake resistor is selected according to the power generated by the motor in the actual applications, related to the system inertia, the deceleration time, the energy of potential load, depending on the customer requirements. The larger system inertia is, the shorter deceleration time is needed; the more frequent brake is applied, the larger power of the brake resistor is selected and the resistance is smaller.

Selection of resistance

During the brake, the recycling energy from the motor is almost consumed on the brake resistor.

According to the formula: U*U/ P= Pb

■ U in the formula – – – brake voltage

(depending on the system, generally take 700V for 380VAC system)

■ pb— brake power

Power selection for brake resistor

In theory, the power for the brake resistor is consistent with the brake power. However, derating is considered as 70%.

According to the formula: 0.7*Pr=Pb*D

■ Pr– resistance power

■ D— brake frequency (The recycling process shares the ratio of the whole work.)

Elevator — -20%~30%

unwind and wind —20%~30%

centrifuge —50%~60%

Sudden brake load –5%

generally take 10%

Brake assembly table (Model G for example)

| Voltage (V) | Power Level | Resistance (Ω) | Capacity (Watt) | Remark |

| 220 | 0.4KW | 200 | 80 | Built-in brake unit |

| 0.75KW | 200 | 80 | Built-in brake unit | |

| 1.5KW | 100 | 150 | Built-in brake unit | |

| 2.2KW | 60 | 250 | Built-in brake unit | |

| 3.7KW | 40 | 300 | Built-in brake unit | |

| 5.5KW | 30 | 500 | Built-in brake unit | |

| 380 | 0.75KW | 360 | 200 | Built-in brake unit |

| 1.5KW | 180 | 400 | Built-in brake unit | |

| 2.2KW | 180 | 400 | Built-in brake unit | |

| 3.7KW | 100 | 500 | Built-in brake unit | |

| 5.5KW | 100 | 500 | Built-in brake unit | |

| 7.5KW | 50 | 1000 | Built-in brake unit | |

| 11KW | 50 | 1000 | Built-in brake unit | |

| 15KW | 40 | 1500 | Built-in brake unit | |

| 18.5KW | 40 | 1500 | Built-in brake unit | |

| 22KW | 30 | 3000 | The brake unit can be customized when ordering. |

|

| 30KW | 20 | 5000 | ||

| 37KW | 20 | 5000 | ||

| 45KW | 15 | 9600 | ||

| 55KW | 15 | 10000 | ||

| 75KW | 10 | 12000 | ||

| 93KW | 8 | 20000 | ||

| 110KW | 8 | 20000 | ||

| 132KW | 6 | 25000 | ||

| 160KW | 6 | 25000 | ||

| The discharge cycle is defined as 10%. | ||||

Remark:

- The brake assemblies are used to consume some potential or energy fed from the load with larger inertia to the frequency inverter, which can avoid inverter trip owing to high voltage. They can be applied for the load with larger inertia and frequent brake or quick parking.

- The brake assemblies belong to peripherals. The brake unit is built in the inverter (0.75-18.5). If the brake function over 22kW is required, please order the inverter with the brake.

- Don’t directly connect the discharge resistor to the P or N terminal. If the inverter terminal is P or N, the discharge block must be additionally installed. If the brake assembly over 93KW is connected to the P or N terminal, please remind us before ordering.

Inverter Dimension and Installation Opening List

| Model Number | W (mm) |

W1 (mm) |

H (mm) |

H1 (mm) |

D (mm) |

d (mm) |

| 9100-1T-00040-G-B | 85 | 77 | 140 | 132 | 125 | Ø3 |

| 9100-1T-00075-G-B | ||||||

| 9100-1T-00150-G-B | ||||||

| 9X00-1T-00220-G-B | 126 | 115 | 170 | 160 | 160 | Ø4 |

| 9X00-3T-00075-G-B | ||||||

| 9X00-3T-00150-G-B | ||||||

| 9X00-3T-00220-G-B | ||||||

| 9X00-3T-00400-G-B 9X00-3T-00550-P-B | ||||||

| 9X00-1T-00400-G-B | 150 | 134 | 220 | 203 | 172 | Ø4 |

| 9X00-1T-00550-G-B | ||||||

| 9X00-3T-00550-G-B 9X00-3T-00750-P-B | ||||||

| 9X00-3T-00750-G-B 9X00-3T-01100-P-B | ||||||

| 9X00-3T-01100-G-B 9X00-3T-01500-P-B | 218 | 108 | 338 | 323 | 228 | Ø9 |

| 9X00-3T-01500-G-B 9X00-3T-01850-P-B | ||||||

| 9X00-3T-01850-G-B 9X00-3T-02200-P | ||||||

| 9X00-6T-01100-G | 265 | 130 | 430 | 420 | 240 | Ø9 |

| 9X00-3T-02200-G 9X00-3T-03000-P 9X00-6T-01500-G | ||||||

| 9X00-3T-03000-G 9X00-3T-03700-P 9X00-6T-01850-G | ||||||

| 9X00-3T-03700-G 9X00-3T-04500-P 9X00-6T-02200-G | ||||||

| 9X00-3T-04500-G 9X00-3T-05500-P 9X00-6T-03700-G | 353 | 200 | 600 | 576 | 299 | Ø11 |

| 9X00-3T-05500-G 9X00-3T-07500-P 9X00-6T-04500-G | ||||||

| 9X00-3T-07500-G 9X00-3T-09300-P 9X00-6T-05500-G | ||||||

| 9X00-3T-09300-G 9X00-3T-11000-P 9X00-6T-07500-G | 397 | 300 | 684 | 600 | 336 | Ø11 |

| 9X00-3T-11000-G 9X00-3T-13200-P 9X00-6T-09300-G | ||||||

| 9X00-3T-13200-G 9X00-3T-16000-P 9X00-6T-11000-G | ||||||

| 9X00-3T-16000-G 9X00-3T-18700-P 9X00-6T-13200-G | ||||||

| 9X00-3T-18700-G 9X00-3T-20000-P 9X00-6T-16000-G | 590 | – | 1114 | – | 410 | – |

| 9X00-3T-20000-G 9X00-3T-22000-P 9X00-6T-18700-G | ||||||

| 9X00-3T-22000-G 9X00-3T-25000-P 9X00-6T-20000-G | ||||||

| 9X00-3T-25000-G 9X00-3T-28000-P 9X00-6T-22000-G | ||||||

| 9X00-3T-28000-G 9X00-3T-31500-P 9X00-6T-25000-G | 692 | – | 1260 | – | 355 | – |

| 9X00-3T-31500-G 9X00-3T-37500-P 9X00-6T-28000-G | ||||||

| 9X00-3T-37500-G 9X00-3T-40000-P 9X00-6T-31500-G | ||||||

| 9X00-3T-40000-G 9X00-3T-45000-P 9X00-6T-37500-G | 814 | – | 1624 | – | 430 | – |

| 9X00-3T-45000-G 9X00-3T-50000-P 9X00-6T-40000-G | ||||||

| 9X00-3T-50000-G 9X00-3T-56000-P 9X00-6T-45000-G | ||||||

| 9X00-3T-56000-G 9X00-3T-63000-P 9X00-6T-50000-G | ||||||

| 9X00-3T-63000-G 9X00-3T-56000-G | ||||||

| 9X00-6T-01100-G | ||||||

| 9X00-3T-00750-ZS-B (integrated cabinet) | 220 | – | 685 | – | 240 | – |

| 9X00-3T-00110-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-01500-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-01850-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-02200-ZS-B (integrated cabinet) | 285 | – | 700 | – | 270 | – |

| 9X00-3T-00300-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-03700-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-04500-ZS-B (integrated cabinet) | 330 | – | 930 | – | 340 | – |

| 9X00-3T-05500-ZS-B (integrated cabinet) | ||||||

| 9X00-3T-07500-ZS-B (integrated cabinet) |

Cùng Chuyên Mục: